Taper Rollers

Taper rollers are the Kansara Group's forte and our rollers have several advantages as compared to the competition.

Unmatched production range

| Length | 8.00 mm to 50.00 mm |

| Larger Diameter | 4.75 mm to 27.00 mm |

| Smaller Diameter | 4.50 mm to 23.50 mm |

| Angle | 2° to 8° 30´ |

Unmatched micro-geometry

The micro-geometry on the scale and quantity of rollers is an engineering challenge at par with the highest technical challenges. Delivering excellence at this has been our goal which has pushed us to pursue frontiers of manufacturing innovations and measuring innovations never before done in the industry. Thanks to our Paradigm-Shifting Modler Grinding Technology, our Taper Rollers have

- Correct, Consistent and Mathematically derived crowned profile on OD to eliminate edge loading and to achieve proper load distribution

- Correct and Consistent sphered end profile on big end for smooth running

- High surface finish for noise reduction

Unmatched cost-effectiveness

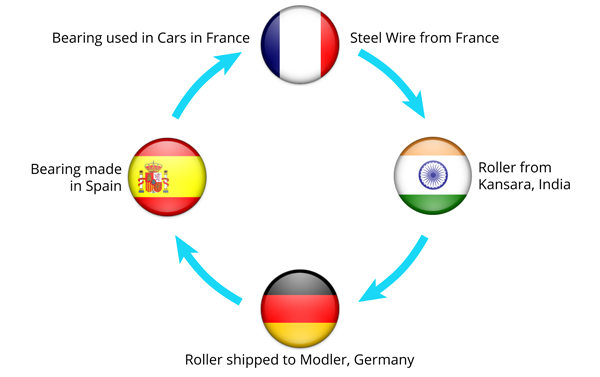

We are a very competitive supplier for rollers as we are the youngest, most technologically advanced and the most cost effective supplier for tapered rollers. Infact, we are so competitive that we export our finished rollers to the very same countries from which we source the raw material for them.

Unmatched alignment of interests

At Kansara, we believe in excellence in our core area i.e. roller manufacturing. As a result, we have steered clear of both forward (i.e. bearings) and backward (i.e. steel and wire) integration. Hence our customers can rest assured that we shall not be competing with them. In short, we are committed to rollers because rollers are our only commitment.

Unmatched world-wide acceptance

Our rollers have become a first choice for customers in economies varying from the very open and competitive to the closed and non-competitive ones. This proves, beyond doubt, the merit of our rollers purely on the grounds of technology, quality and cost- effectiveness.